Be first to know

Keep up to date with ecommerce news, trends and articles. Brought to you by Stock2Shop.

Sign up todayBusinesses often operate across multiple locations to expand their reach and optimise distribution. However, managing inventory across these diverse locations presents significant challenges that can impact efficiency, customer satisfaction and overall profitability. To address these challenges effectively, companies must adopt strategic approaches and utilise advanced technologies. Here are some tips and best practices.

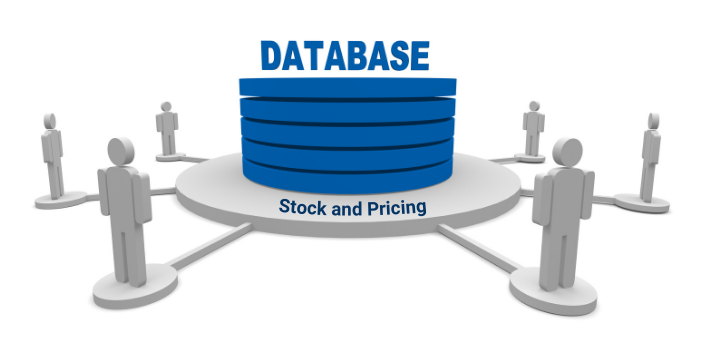

Implementing a centralised inventory management system is crucial for maintaining control and visibility across all locations. This system serves as a single source of truth, consolidating data on stock levels, orders and movements in real-time. By centralising inventory data, businesses can avoid overstocking or stockouts, optimise replenishment cycles and enhance decision-making.

Modern inventory management systems often take the form of ERP (Enterprise Resource Planning) or WMS (Warehouse Management) software. These technologies streamline operations, minimise manual errors and provide accurate insights into inventory performance across different locations.

Establishing standardised processes and protocols ensures consistency across all locations. This includes defining procedures for receiving goods, picking and packing orders, conducting stock audits and managing returns. Once all locations are operating in a uniform way, businesses can improve operational efficiency and enhance overall reliability in inventory management.

Training staff members on these processes is equally essential. Proper training ensures that employees understand their roles and responsibilities, adhere to operational guidelines and utilise inventory management tools effectively. Regular audits and performance reviews can further reinforce compliance with established protocols.

Accurate demand forecasting is critical for optimising inventory levels across multiple locations. By analysing historical sales data, market trends and seasonal fluctuations within your ERP or WMS, businesses can predict demand patterns and adjust inventory levels accordingly. Advanced forecasting models, powered by machine learning algorithms, can provide more precise insights into future demand, enabling proactive inventory planning.

Inventory optimisation techniques, such as ABC analysis and economic order quantity (EOQ), help businesses prioritise stock replenishment based on item importance and order frequency. This strategic approach minimises storage costs, reduces excess inventory and ensures that high-demand items are readily available at all locations.

Real-time visibility into inventory movements and stock levels is essential for proactive decision-making and responsive customer service. Inventory management systems offer real-time updates across all locations, enabling stakeholders to monitor inventory metrics, track shipments and identify potential issues promptly.

Comprehensive reporting capabilities provide actionable insights into inventory performance, such as turnover rates, fill rates and carrying costs. By analysing these metrics, businesses can identify operational inefficiencies, optimise inventory allocation and make data-driven adjustments to their supply chain strategies.

Effective communication and collaboration between locations are key to maintaining seamless inventory operations. Establishing cross-location coordination mechanisms, such as regular meetings or virtual collaboration tools, facilitates information sharing, problem-solving, and decision alignment among different teams.

Embracing technology and automation streamlines inventory management processes and enhances operational efficiency. Automated reorder triggers, for example, automatically generate purchase orders when inventory levels reach predefined thresholds, minimising stockouts and improving inventory turnover.

Technology is especially important when a company sells online. It’s vital that all ecommerce sales channels, from web stores to online marketplaces, have a line of sight to accurate inventory data stored within the ERP. Stock2Shop can facilitate the distribution of this data to ecommerce channels, and also automate orders back into the ERP for greater efficiency.

Some companies prefer to establish a virtual warehouse for ringfencing ecommerce inventory. While this reduces the chance of overselling, it does increase the risk of missing sales opportunities when that virtual warehouse is depleted. With Stock2Shop, you can mitigate this risk by considering inventory across multiple warehouses when syncing stock availability to your online platforms.

Continuous monitoring and optimisation are essential for maintaining peak performance in multi-location inventory management. Regularly assessing key performance indicators (KPIs), conducting root cause analyses of discrepancies and soliciting feedback from stakeholders enable businesses to identify areas for improvement and implement corrective actions promptly.

By staying agile and adaptable, businesses can sustain operational excellence and a competitive advantage in inventory management.

If your vital product data (such as stock and pricing) across your various locations is managed on a centralised system that is visible to all stakeholders, you’re most of the way to workflow efficiency. But if your ecommerce platforms are not “speaking” to this system, you have an operations hole that needs to be plugged.

Whether you’re a wholesaler (B2B) or retailer, contact us to find out how you can put your ERP or WMS system in charge of your online business.

Keep up to date with ecommerce news, trends and articles. Brought to you by Stock2Shop.

Sign up todayUnderstanding product data is essential for a successful ecommerce business. Here’s an overview of the most important elements of product data you need to understand.

Read MoreCategorising products correctly is a major pain point for many ecommerce websites. Layered navigation is the solution: find out how – and why – to implement it

Read MoreWant to find out exactly how Stock2Shop can make your business more efficient and streamlined?

Contact Us